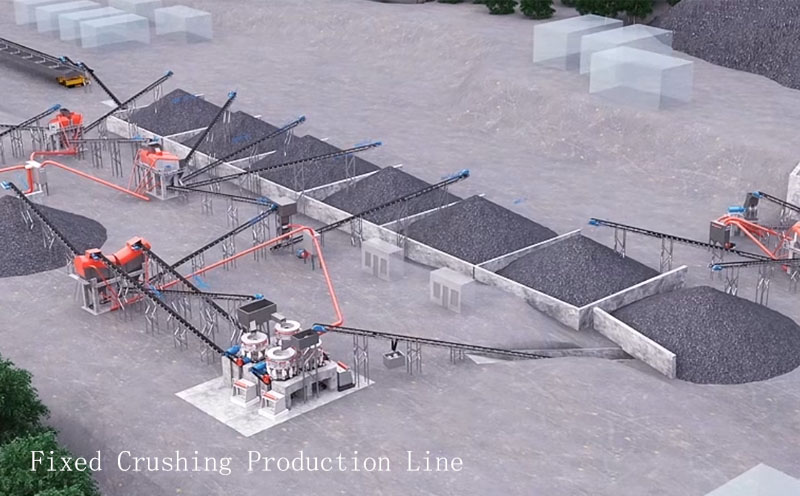

Generally, mining crushing is divided into three stages: primary crushing, secondary crushing, and tertiary crushing, which is determined by factors such as the particle size of the material to be crushed, its hardness (e.g., granite, limestone), the hardness differences between different minerals (e.g., iron ore, copper ore for metal ores), and the required fineness of the crushed product.

Raw Ore Conveying and Feeding: Large pieces of raw ore extracted from the mine are transported to the primary crushing workshop via belt conveyors. A vibrating feeder then feeds the ore uniformly into a jaw crusher (primary crushing equipment) to prevent material accumulation and blockage.

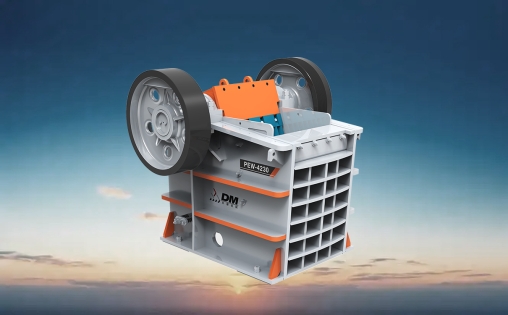

Primary Crushing Stage: The jaw crusher crushes the raw ore (with an initial particle size of 1-3 meters) into "coarse aggregates" with a particle size of 50-200 mm. The crushed material is then transported to a vibrating screen via a belt conveyor for the first round of screening.

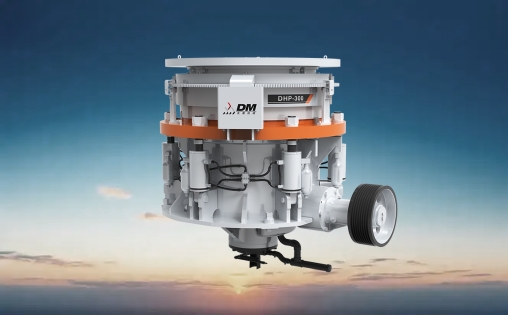

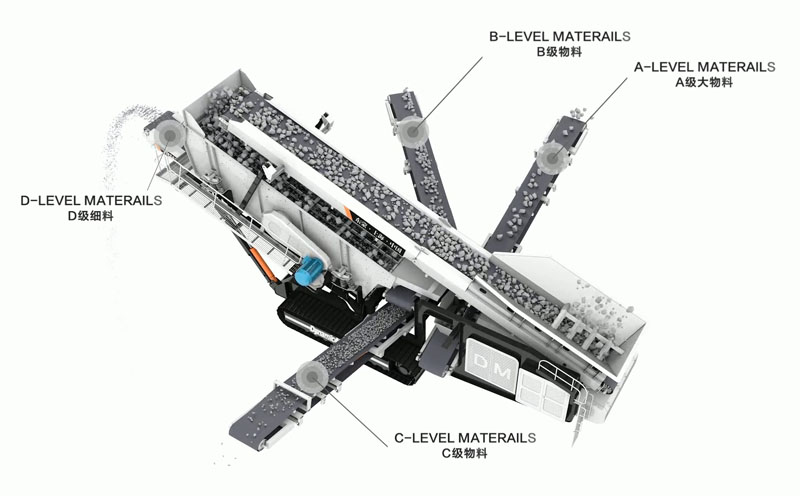

Secondary Crushing Stage: The vibrating screen separates the coarse aggregates that meet the particle size requirement (e.g., 50-200 mm) and feeds them into a cone crusher (secondary crushing equipment). Aggregates with an excessively large particle size are returned to the jaw crusher for "re-crushing". The cone crusher further crushes the material into particles with a size of 10-50 mm, which are then sent back to the vibrating screen for re-screening.

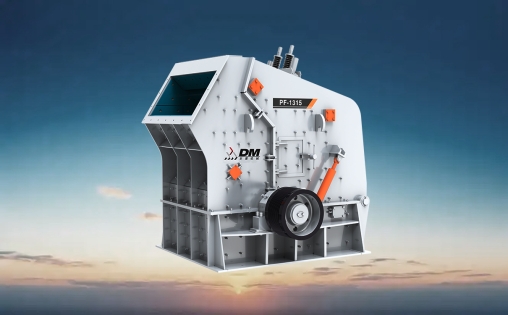

Tertiary Crushing Stage: The material that meets the requirements after secondary crushing (with a particle size of 10-50 mm) is fed into an impact crusher (tertiary crushing equipment), where it is crushed into "fine aggregates" with a particle size of 1-10 mm. Finally, the fine aggregates are sent to the vibrating screen for the final classification. Those with a qualified particle size are transported to the mineral processing workshop, while those that fail the classification are returned to the tertiary crushing equipment for re-crushing.

Auxiliary Treatment: In some processes, "impurity removal equipment" (such as magnetic separators for separating metal impurities and iron removers for removing waste iron) or "dust removal equipment" (such as pulse dust collectors for treating dust generated during the crushing process) is added. These devices help reduce environmental pollution and protect the main crushing equipment at the same time.

English

English

简体中文

简体中文

عربي

عربي

Русский

Русский

Français

Français

Español

Español