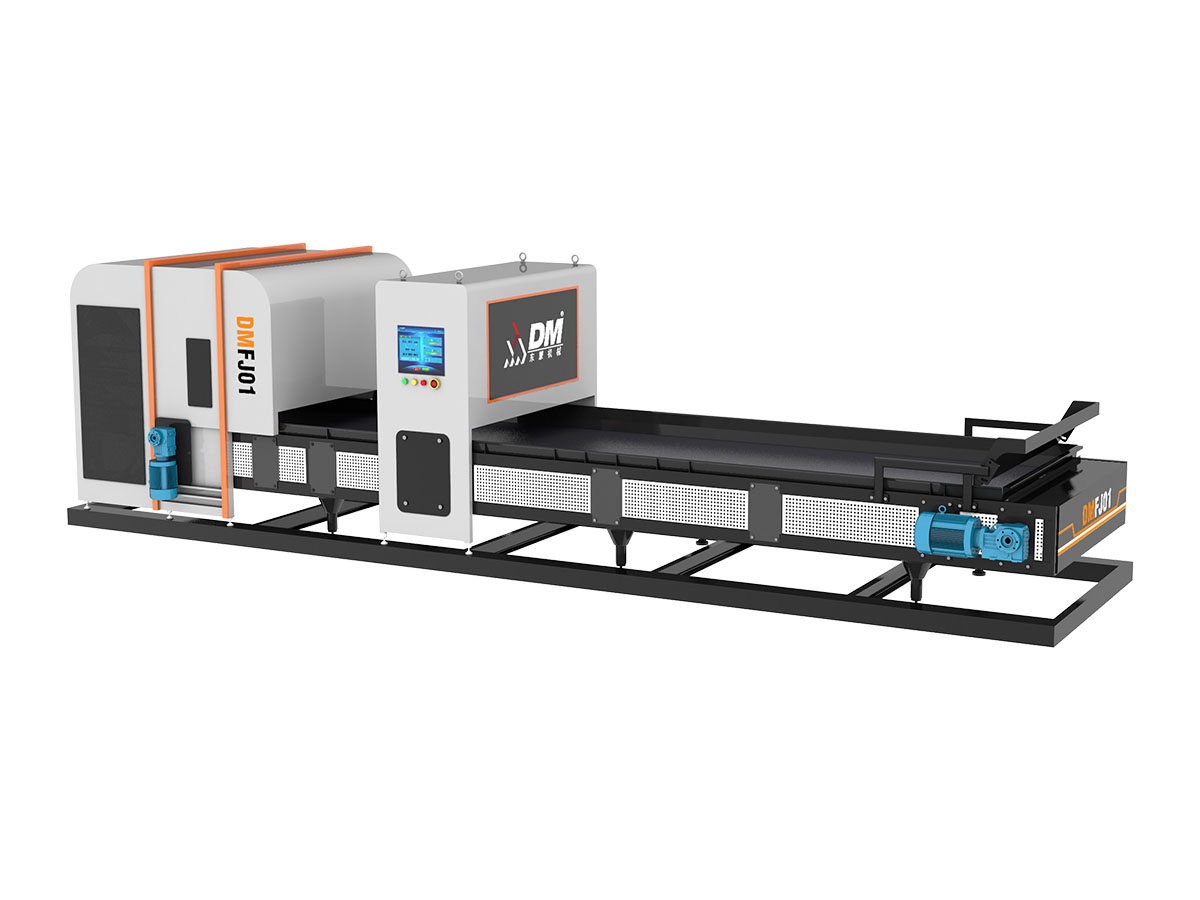

Product Details:

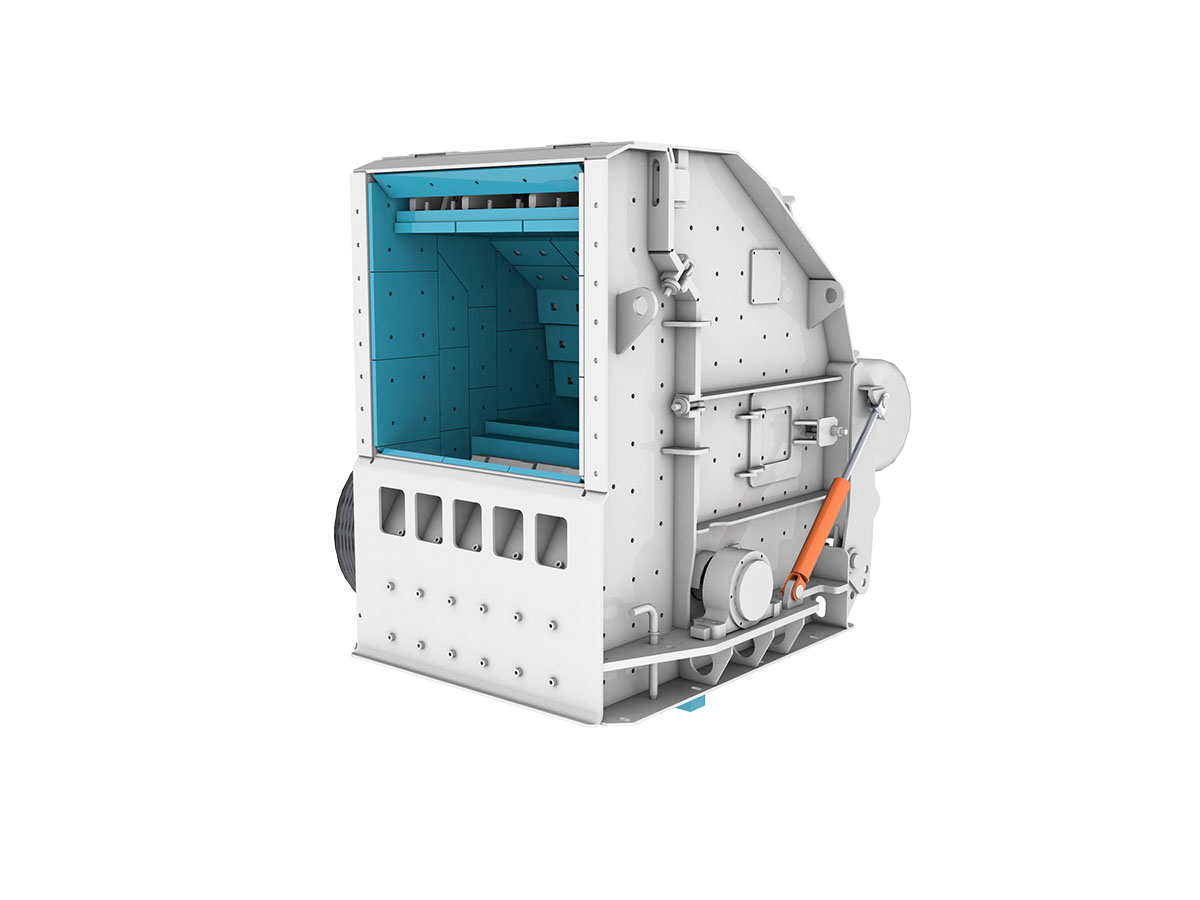

Hydraulic large diameter impact crusher adopts unique designs such as heavy rotor, large-capacity crushing chamber, thick impact plate, high-wear-resistant alloy blow bar, hydraulic opening device, etc. It has the advantages of greater crushing capacity and crushing ratio, low operating cost and convenient maintenance.

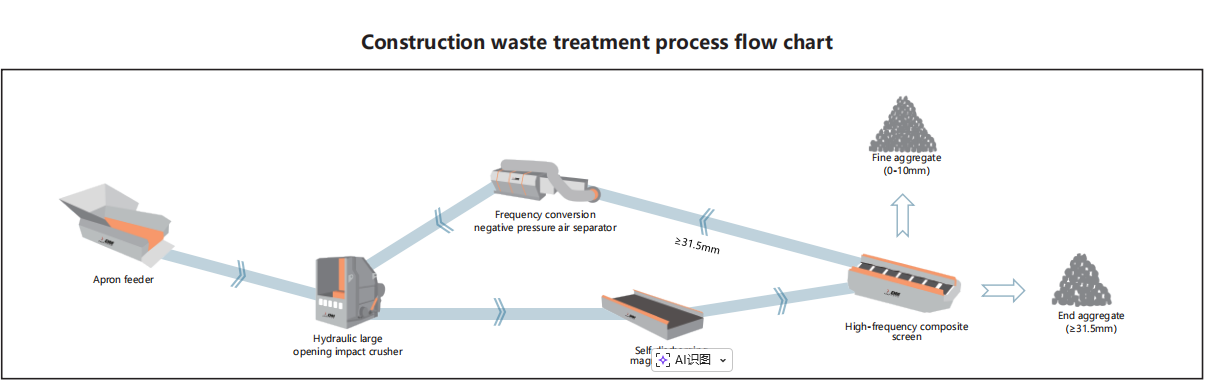

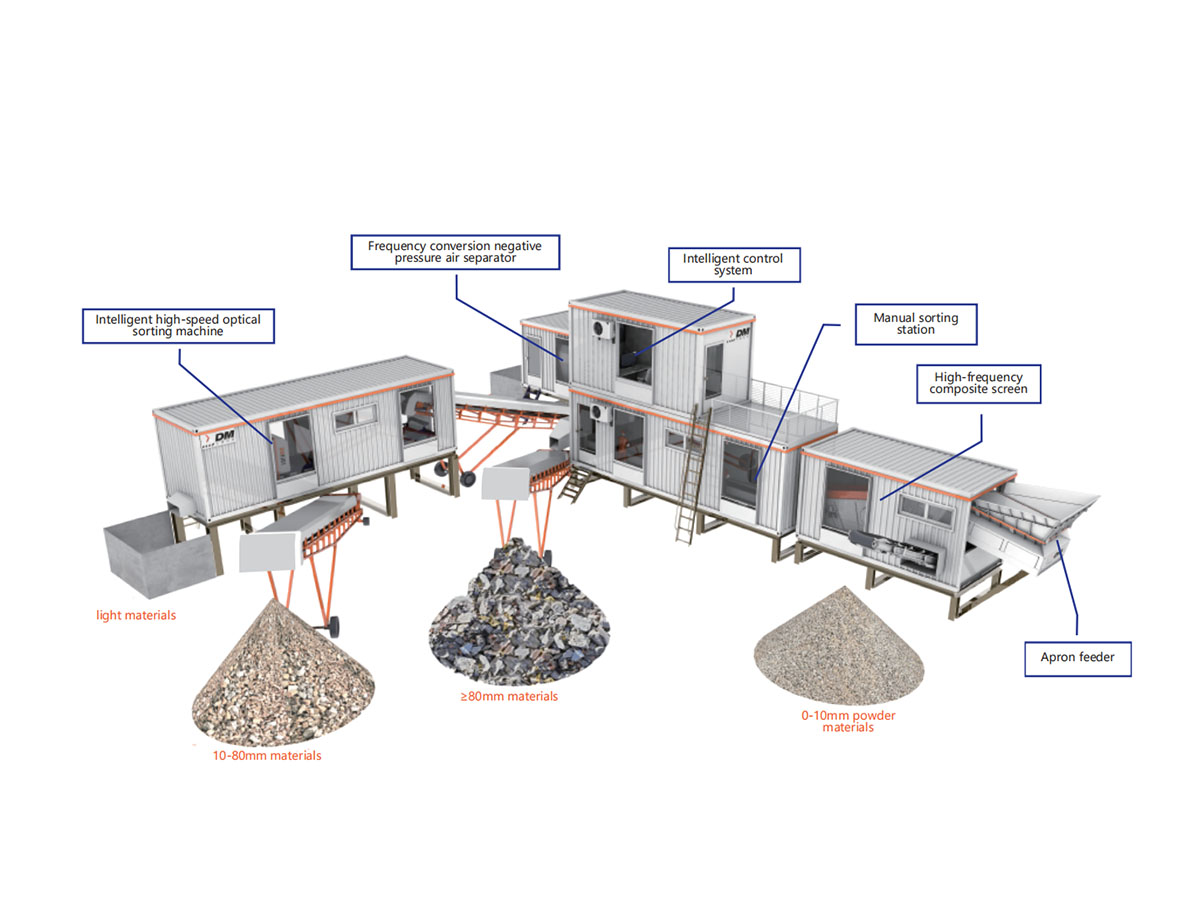

Application-Construction waste disposal solution

construction waste

Defined as residual soils, excavated materials, demolition debris, slurry, and other waste

substances generated during construction, demolition, or renovation activities by construction units or individuals on buildings, structures, pipelines, and related infrastructure.

Solution description:

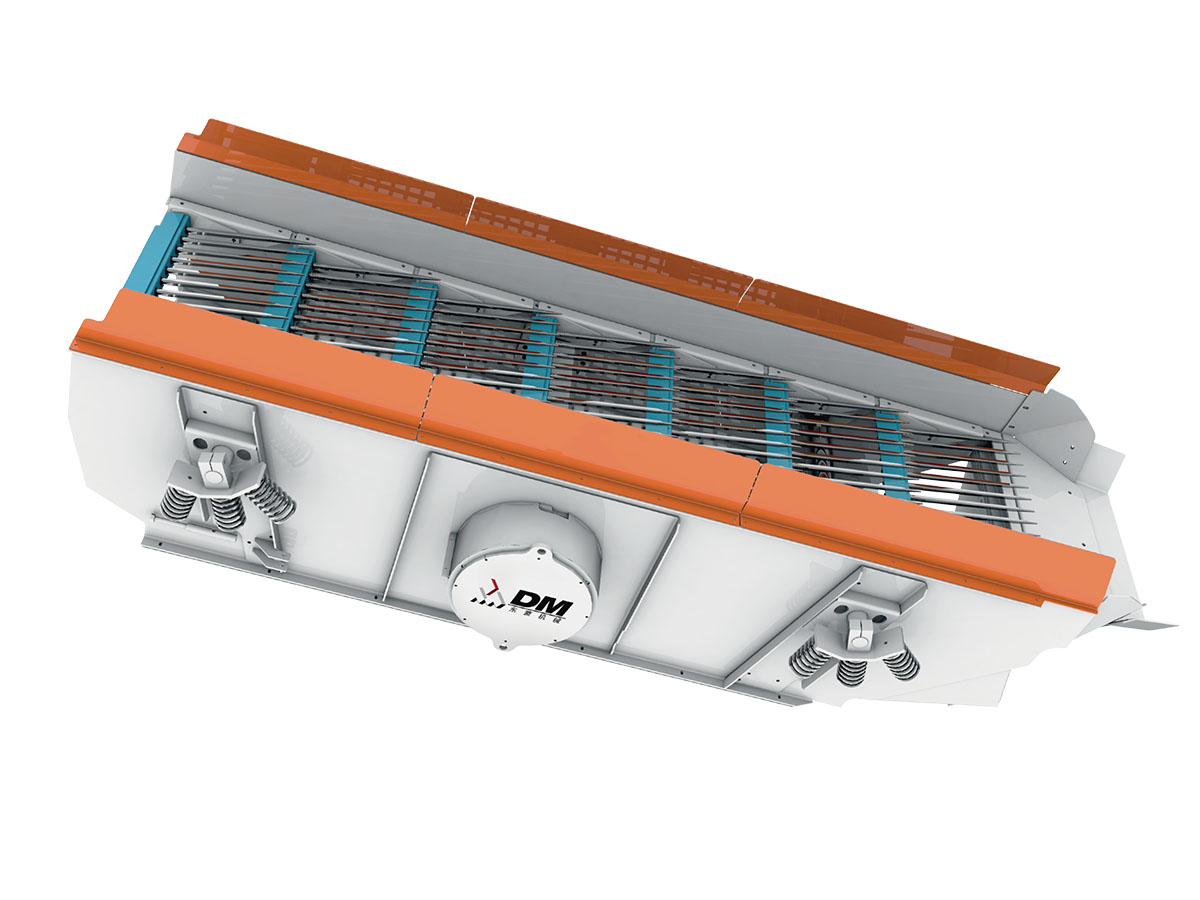

Our system utilizes hydraulic jaw crushers, large-diameter impact crushers, high frequency composite screens, and lightweight material sorting equipment to execute a streamlined conversion process.

Product Parameters:

Performance Requirements for Impact Crushers

• Impact Crusher (DMI1313): Impact crushing; Sealing treatment for feed and discharge ports of the anti-impact crusher to prevent dust leakage; Bearing seats are cast integrally with cast steel; Rotors adopt segmented welding process; Full hydraulic adjustment is used, including hydraulic station, hydraulic iron remover, hydraulic adjustment of discharge port, and hydraulic cover opening.

• Impact Crusher (DMI1013): No additional special performance requirements specified (main requirements are reflected in technical parameters).

| Equipment Name | Parameter Item | Parameter Content |

|---|---|---|

| Impact Crusher DMI1313 |

Maximum Feed Size | ≤500mm (to meet the feeding of heavy materials in decoration waste) |

| Processing Capacity | ≥150t/h (calculated based on medium-hardness materials with a density of 1600KG/cubic meter) | |

| Rotor Dimension | ≥Φ1300×1300mm | |

| Number of Crushing Chambers | 2 | |

| Impact Liner & Hammer Material | Impact liner wear resistance: Not less than ZGMn13Cr2; Hammer material: KmTBCr26 | |

| Installed Power | ≥220kw, soft start mode | |

| Drive Motor Brand / Protection Class | Leibo; IP55 | |

| Lubrication Method | Grease lubrication | |

| Impact Crusher DMI1013 |

Maximum Feed Size | ≤400mm (to meet the feeding of heavy materials in decoration waste) |

| Processing Capacity | 50-80t/h | |

| Material Return Rate | ≤30% | |

| Installed Power | 75kw, soft start mode | |

| Drive Motor Brand / Protection Class | Leibo or domestic equivalent grade; IP55 | |

| Impact Liner & Hammer Material | Impact liner wear resistance: Not less than ZGMn13Cr2; Hammer material: KmTBCr26 | |

| Bearing | TMB | |

| Frame Opening Method | Hydraulic opening method |

English

English

简体中文

简体中文

عربي

عربي

Русский

Русский

Français

Français

Español

Español

Get In Touch With Us